| GENERAL DESCRIPTION |

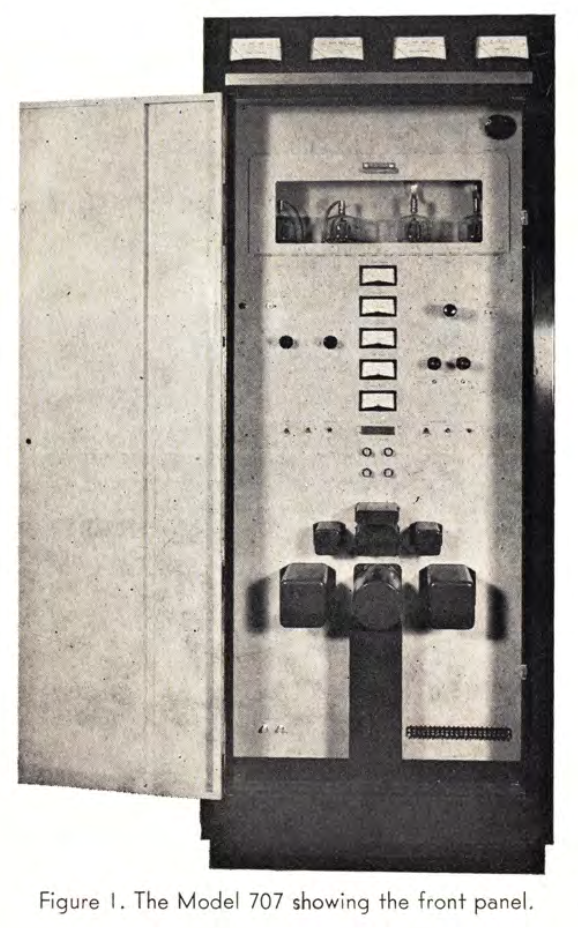

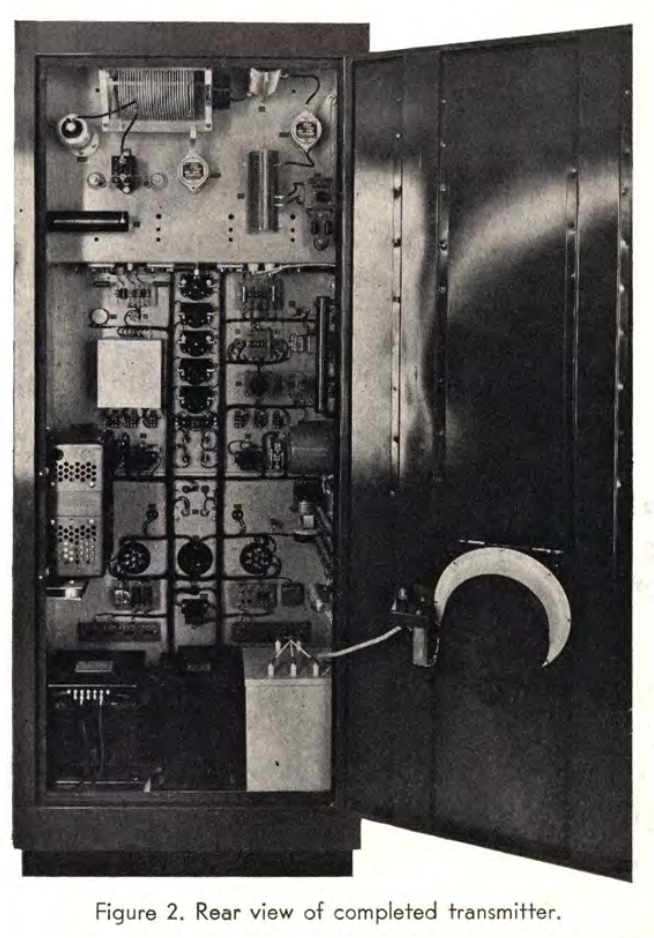

DESIGN FEATURES OF A BROADCAST TRANSMITTER KIT

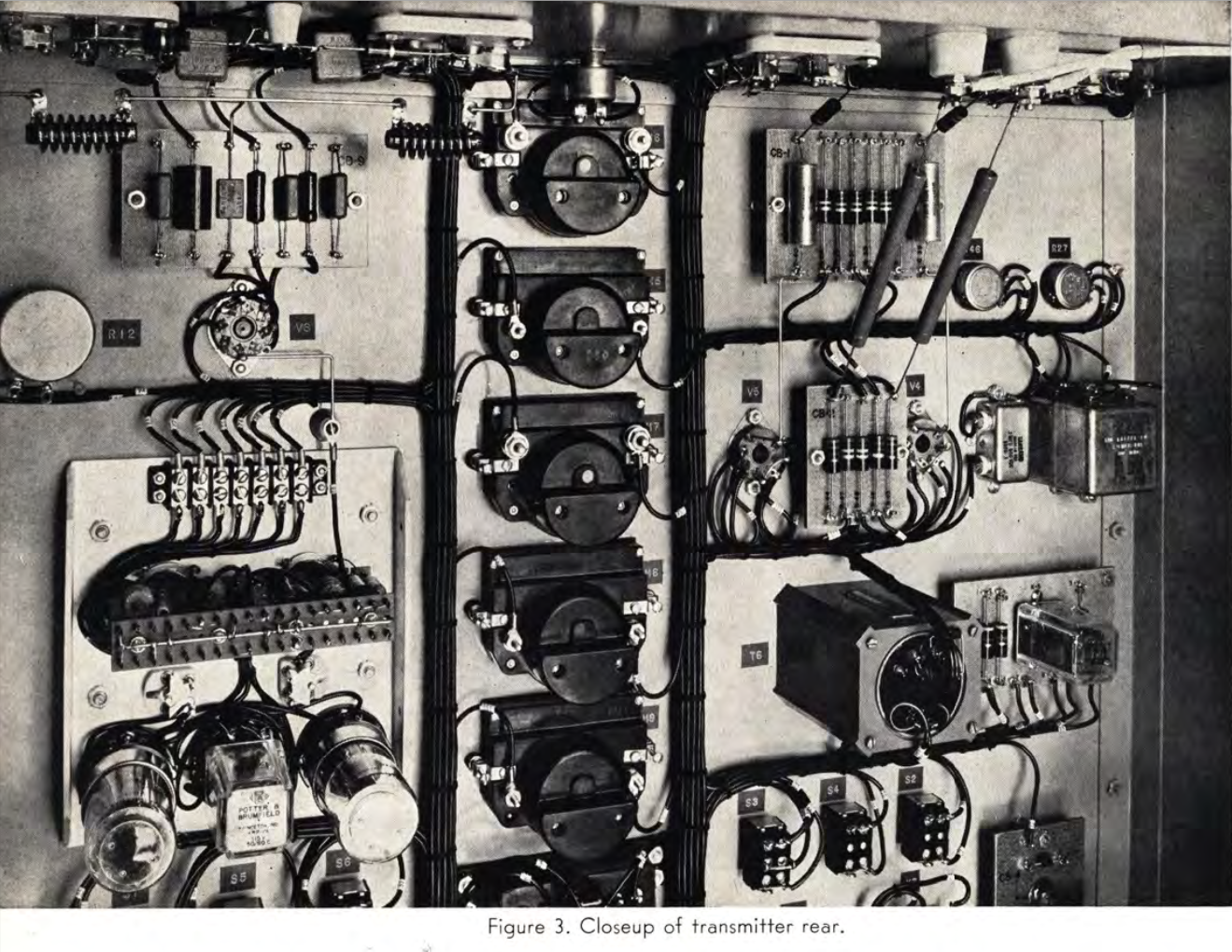

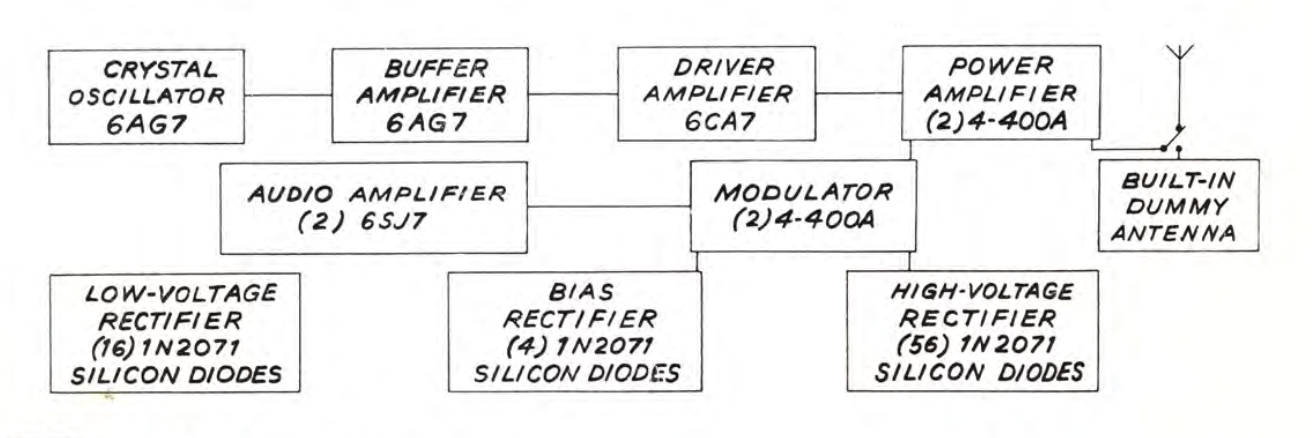

DESIGN FEATURES OF A BROADCAST TRANSMITTER KIT The RF Section

The RF Section The AF Section

The AF Section The Power Supplies

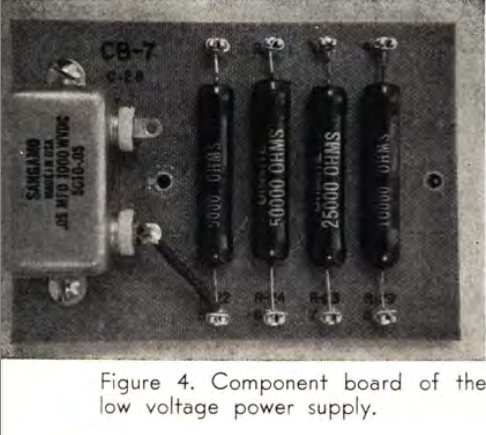

The Power Supplies

| TECHNICAL SPECIFICATIONS | |

| Type Of Emission | A3 |

| Rated Power Output | 1000/500/250 watts |

| Power Output Capability | 1100 watts |

| R.F. Output Impedance | 50 ohms, unbalanced |

| Frequency Range | 540-1600 Kc |

| Frequency Stability | ±5 cps |

| Audio Input Level (100% mod.) | 10 dbm |

| Frequency Response (0-95% mod.) | 1000/500/250 watts 50-10,000 cps : ±0.5 db 30-12,000 cps : ±1.5 db |

| Distortion (0-95% mod.) | 1000/500/250 watts 50-10,000 cps : 2.0% max |

| Carrier Shift | 1000/500/250 watts less than 3% |

| Noise Level (below 100% mod.) | 1000 and 500 watts : -60 db 250 watts : -57 db |

| Power Consumption | (For one kilowatt carrier power) Average modulation : 3300 watts 100% modulation : 3950 watts |

| Power Requirements | 208-240 volts 50/60 cycles Single phase |

| Dimensions | Height : 75" Width : 30" Depth : 25" |

| Net Weight | 800 pounds (approx.) |

| Specifications may change without notice | |

| TUBE COMPLEMENT | |||

| RF stages | AF stages and modulator | ||

| Number | Type | Number | Type |

| 2 | 4-400A | 2 | 4-400A |

| 3 | 6AG7 | 2 | 6SJ7 |

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| CAN | CANADA | COD | CONGO DEMOCRATIC REPUBLIC | ||

| VEN | VENEZUELA | ||||