| GENERAL DESCRIPTION |

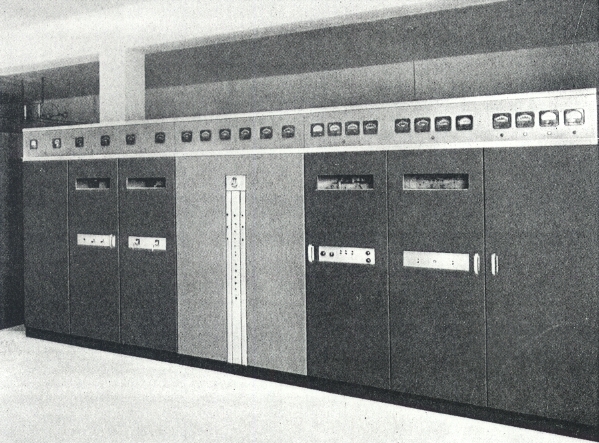

The BHF-50A transmitter is a 50 KW AM High Frequency broadcast transmitter designed for high fidelity service in the International Broadcast bands from 3.0 to 26.1 megacycles. The transmitter is entirely air cooled. The number of tuning adjustments are held to a minimum by the use of grounded grid amplifiers and by the use of ganged circuit elements. The use of remotely controlled motor driven circuit elements permits tuning the transmitter to any frequency within the range of 3.0 to 22 megacycles within an elapsed time of 2 minutes, with slightly longer time required for changing to tho 26.1 band. Features include a unified front, streamline styling, centralized power and control units, and dead front construction.

The BHF-50A transmitter is a 50 KW AM High Frequency broadcast transmitter designed for high fidelity service in the International Broadcast bands from 3.0 to 26.1 megacycles. The transmitter is entirely air cooled. The number of tuning adjustments are held to a minimum by the use of grounded grid amplifiers and by the use of ganged circuit elements. The use of remotely controlled motor driven circuit elements permits tuning the transmitter to any frequency within the range of 3.0 to 22 megacycles within an elapsed time of 2 minutes, with slightly longer time required for changing to tho 26.1 band. Features include a unified front, streamline styling, centralized power and control units, and dead front construction. Circuit Description

Circuit Description

| TUBE COMPLEMENT | |||||

| RF stages | AF stages and modulator | Rectifiers | |||

| Number | Type | Number | Type | Number | Type |

| 3 | 9C25 | 2 | 9C25 | 6 | 857B |

| 1 | 5762 | 8 | 813 | 2 | 8008 |

| 3 | 5-125B / 4E27A | 2 | 5-125B / 4E27A | ||

| 2 | 807 | ||||

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| D | GERMANY | POR | PORTUGAL | ||