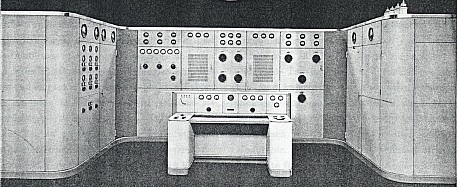

| GENERAL DESCRIPTION |

5 kW TROPICPROOF SHORTWAVE BROADCAST TRANSMITTER

5 kW TROPICPROOF SHORTWAVE BROADCAST TRANSMITTER| TUBE COMPLEMENT | |||||

| RF stages | AF stages and modulator | Rectifiers | |||

| Number | Type | Number | Type | Number | Type |

| 2 | PAL 12/15 | 2 | PE 06/40 | 2 | 506 |

| 2 | PB 3/1000 | 1 | EB 4 | 11 | DCG 4/1000 |

| 2 | PE 1/80 | 3 | EBC 3 | 6 | DCG 5/2500 |

| 2 | PE 04/10 | 1 | EL 5 | 2 | 1561 |

| 4 | CC 2 | 1 | EL 3 | ||

| 8 | EZ 4 | ||||

| 2 | 1561 | ||||

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||