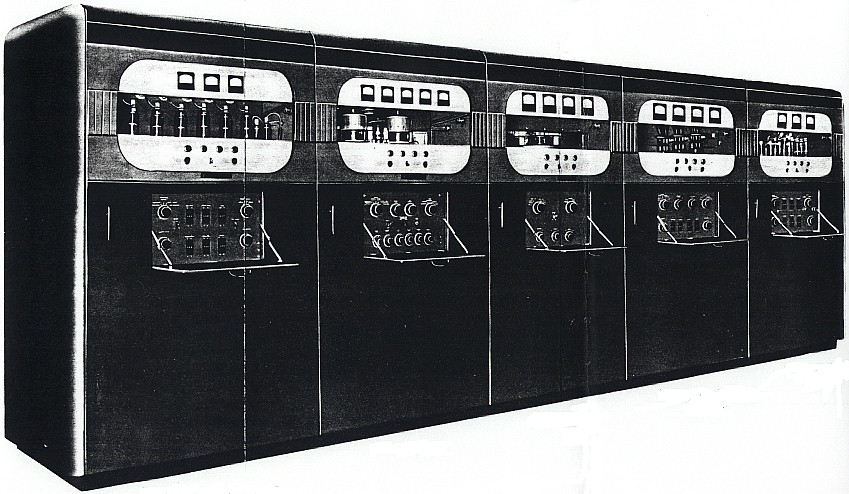

| GENERAL DESCRIPTION |

1. PURPOSE

1. PURPOSE| TECHNICAL SPECIFICATIONS | |

| Total Cubical Contents | 687 cubic feet (not crated) |

| Total Weight | 16,800 pounds (not crated) |

| Frequency range | 4000 to 26000 kilocycles |

| Frequency Multiplier Range | 4 to 26 megacycles |

| First Frequency Multiplier | 4 to 13 megacycles |

| Second Frequency Multiplier | 4 to 26 megacycles |

| Type of Frequency Control | Crystal or Stabilized Oscillator |

| Type of Emission | a. A-3 (Amplitude modulated) b. A-1 (Carrier ON-OFF) c. Frequency Shift |

| Keying Speed | Up to 400 wpm both off-on and frequency shift emission. |

| Keying input Circuit Impedance | 25,000 ohms - one line grounded |

| Nominal Carrier Output for Each Type of Emission | a. 35 kw for AM emission into a fixed 600 ohm load with a maximum SWR of 2 to 1 b. 50 kilowatts for A-1 emission, into a fixed 600 ohm load with a maximum SWR of 2 to 1 c. 50 kilowatts for frequency shift emission into a fixed 600 ohm load with maximum SWR of 2 to 1 |

| Power Factor of Equipment | a. Starting: 82.5% (High Voltage Off) b. Standby: 80.5% (Key Open) c. Normal Operation: 96% |

| Power Source Requirements | a. Voltage: 207 to 253 volts; designed for a center voltage of 230 b. Frequency: 60 cps ±5% or 50 cps ± cps c. Number of Phases: 3 Phase d. Input Power: AM Unmodulated: 86 kw 100% modulated: 130 kw CW Key Down: 92 kw CW Key Up: 15.6 kw CW High Voltage Off: 11.2 kw e. Regulation Tolerance: 5% voltage variation from no load to 130 kw f. Protective Devices: Power Source fused or otherwise protected for 600 amp (max.) current to a 140 KVA load; must limit short-circuit current to 10,000 amps |

| Crystal | Type AN/CR-27/U with fundamental frequency between 2.0 and 4.2 mc required (Not Supplied by Contractor) |

| Modulation Method | High level Class B-1 |

| Modulation Capability | 100 percent |

| Audio Input Level for 100% Modulation | +10 ±2 dbm into 150/600 ohm input impedance |

| Audio Frequency Response | Equal to or better than ±2 db between 150 and 7500 cycles per second and ±4 db from 50 to 10,000 cycles |

| Audio Frequency Harmonic Distortion | Less than 5% RMS for fundamental frequencies 50 to 7500 cycles per second for values of modulation 0 to 90% |

| Carrier Frequency Stability | 5 cycles per megacycle |

| Carrier Noise Level | AM - 50 db below 100% modulation over band of 70 to 7500 cycles CW - Less than 3% equivalent amplitude or phase modulation |

| Carrier Shift | 5% maximum at 90% modulation |

| Ambient Temperature Range for Satifactory Operation | 0 to 50°C (32°F to 122°F) |

| Elevation Above Sea Level for Satisfactory Operation | 6000 feet maximum |

| Specifications may change without notice | |

| TUBE COMPLEMENT | |||||

| RF stages | AF stages and modulator | Rectifiers | |||

| Number | Type | Number | Type | Number | Type |

| 8 | 3X2500A3 | 2 | 4-250A | 8 | 3B28 |

| 1 | 4-400A | 6 | 8C25 | 18 | 4B32 |

| 1 | 6AK5 | 1 | 12AX7 | ||

| 10 | 6X4 | 2 | 4B32 | ||

| 2 | 6AG7 | ||||

| 2 | 807 | ||||

| 10 | 12AU7 | ||||

| 9 | 12AX7 | ||||

| 2 | VR90 | ||||

| THIS TYPE OF TRANSMITTER IS INSTALLED IN THE FOLLOWING COUNTRIES | |||||

| ITU | Country | ITU | Country | ||

| D | GERMANY | GRC | GREECE | ||

| J | JAPAN | MRC | MOROCCO | ||

| PHL | PHILIPPINES | CLN | SRI LANKA | ||